지속 가능성의 오랜 유산

Title:환경을 보호하고 전 세계와 지역 사회에 긍정적 영향력을 발휘하기 위해 지속적으로 투자해 왔습니다.

사회적 책임

Title:1900

Swarovski Music Club 및 Swarovski Cycling Club 창립. 사내 활동을 위해 당초 설립된 이들 클럽은 모든 지역 주민이 빠르게 이용할 수 있게 되었습니다. 다니엘 스와로브스키는 두 클럽에서 활발하게 활동한 회원이었습니다.

1908-1909

1902년 7월 25일, 다니엘 스와로브스키는 바텐스 지역 의회의 일원이 되었습니다. 1908년 지역 의회 의장으로 선출된 그는 1년 후인 1909년에 마을의 담수 공급을 위한 새로운 파이프라인 건설을 시작했습니다.

1909

회사의 많은 직원들과 그 가족들이 바텐스로 이사를 오게 되자, 마을의 기존 학교는 너무 작아서 아이들을 모두 수용할 수 없었습니다. 다니엘의 아내 마리 스와로브스키는 새로운 학교 설립을 위한 건축 부지를 기부했습니다.

1959

스와로브스키는 오스트리아에서 유일한 크리스털 커팅을 포함해 8가지의 다양한 전문 분야를 아우르는 맞춤형 교육 과정을 제공했습니다.

1960

“다니엘 & 마리 스와로브스키 기금(Daniel and Marie Swarovski Trust)을 설립하여 티롤에 거주하는 성적이 우수한 저소득 가정의 학생들에게 장학금 혜택을 제공했습니다.

1978

사내에 "직업 대학"을 설립하고 견습 과정을 제공하여 직장에서 기술과 적성을 발휘하기 위한 견고한 기반을 마련했습니다. 스와로브스키는 오스트리아에서 이러한 대학 기관을 가진 몇 안 되는 기업 중 한 곳입니다.

물의 힘을 활용하다

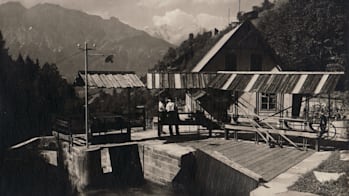

Title:1907

스와로브스키 최초의 대규모 수력발전소, Ausserachen이 설립되었습니다. 3개의 펠톤 터빈이 깨끗한 “Swarovski 전력”을 절단기에 공급하고, 작업 공간뿐 아니라 바텐스와 인근 산악 지역에 이르는 폭넓은 면적에 전기불을 제공했습니다.

1951

Ausserachen 수력발전소는 750KW 출력을 제공하도록 업그레이드되었습니다.

1961

청정에너지 수요가 증가함에 따라, 2개의 프랜시스 터빈을 통해 2,200KW 출력을 제공하는 Innerachen 발전소가 건립되었습니다.

1983

Wattens 제지 공장과 협력하여 Wattenbach 수력발전소가 설립되었습니다. 이 발전소는 연간 평균 57GWh의 전력을 생산합니다.

1984

추가적인 이중 노즐의 펠톤 터빈을 사용해 Innerachen 발전소의 표준 생산 용량을 1.35GWh으로 확대했습니다.

1995

알프스의 친환경 에너지 생산을 위한 모범 프로젝트인 “Haneburger” 발전소가 가동을 시작했습니다. 이 발전소는 연간 약 18.5GWh의 전력을 공급해왔습니다.

2001

오스트리아 당국은 모든 스와로브스키 발전소의 "친환경 전력" 생산에 대해 공식적으로 인정했습니다.

모두를 위한 집

Title:1947

바텐스 인근 언덕인 “Kreuzbichl”에 새로운 사택을 짓기 위한 토대를 마련했습니다. 이 건물은 1950년에 완공되었습니다. 지금까지 몇 차례에 걸쳐 추가로 사택 프로젝트를 실현했습니다.

1948

직원들의 사회적 및 경제적 어려움을 해소하기 위해 회사 소유의 복지 사무소를 설립했습니다. 스와로브스키의 사택 정책은 저금리 주택 신용대출과 주택 건설을 위한 물질적 지원, 긴급 재난지원금 등을 제공했습니다.

1951

오스트리아 압삼의 Swarovski Optik 직원들과 볼더스의 Swarovski 직원들을 위한 두 곳의 사택 단지 건설에 착수/완공했습니다.

1952

오스트리아 프리첸스에서 스와로브스키 직원들을 위한 추가 사택 단지 건설에 착수/완공했습니다.

2005

직원들을 위한 58개의 신축 연립 주택의 개소식을 가졌습니다. 이 프로젝트를 통해 직원들이 합리적인 가격으로 주거 공간을 임대 또는 구입할 수 있게 되었습니다.

귀중한 자원

Title:1970

공기 압축 냉각을 위해 첫 번째 순환 냉각탑을 가동했습니다. 이를 통해 약 90%의 냉각수를 절약할 수 있었습니다.

1978-1982

폐수 정화장을 가동하여 제1공장에서 발생하는 모든 물을 정화했습니다. 일련의 후속 조치를 통해 폐수정화 시스템을 제2공장으로 확대했으며, 정수장 기능을 확장하고 공정 용수를 연마수와 절단순환수로 분리했습니다.

보다 맑은 공기

Title:1984

스와로브스키는 유황 함량이 낮은 난방용 석유를 독일로 수입해 오늘날 연간 간접비가 21만 유로로 증가했지만, 이산화황 배출량은 60톤까지 감축했습니다. 이에 따라 스와로브스키는 티롤 연방 주정부로부터 “Green Branch” 환경상을 수상했습니다.

1990

스와로브스키는 천연가스를 도입했습니다. 이제 열 발생 및 크리스털 용해를 위한 난방유를 가스로 대체해 각 단계에서 이산화탄소 배출량을 30%까지 감축할 수 있게 되었습니다.

1996

유리 제조 부서는 새로운 특수 먼지 필터와 추출 시스템을 마련했습니다. 이를 통해 배출량을 줄이고 오염을 방지하며, 근로자의 건강 문제를 법적 제한보다 훨씬 낮게 유지했습니다.

스와로브스키 워터스쿨

Title:2000

다뉴브강 유역에 위치한 오스트리아 호헤타우에른 국립공원에 첫 번째 스와로브스키 워터스쿨이 문을 열었습니다. 이 워터스쿨은 교육 프로그램을 도입하여 어린이와 청소년을 대상으로 수자원의 중요성과 물부족 문제에 대한 교육을 제공합니다.

2006

오스트리아 외에서 진행된 첫 프로젝트인 인도의 스와로브스키 워터스쿨은 갠지스강 유역의 라자스탄에 위치한 케올라디오 국립공원 인근에 문을 열었습니다.

2008

스와로브스키 워터스쿨은 중국 양쯔강 주변의 6개 지역과 우간다 카눈구의 20개 지역에서 운영을 시작했습니다.

2014

스와로브스키 워터스쿨은 브라질 북부의 파라 주에 개장하여 수자원 및 환경 교육을 중심으로 학교와 지역사회 기반의 참여 학습을 제공하고 있습니다.

2016

다양한 기관과 함께 3개의 파일럿 프로젝트에 착수하여 지역의 수자원을 집중 조명했습니다. NGRREC: 미시시피강, 락타이 재단, 짜오프라야강 유역, 지속 가능한 아마존 재단: 아마존.

2017

스와로브스키 워터스쿨은 NGO 파트너들과의 협력을 통해 스와로브스키 워터스쿨 웹사이트에서 ‘강을 변화시키는 한 방울의 지식’이라는 교육 및 학습 자료의 글로벌 에디션을 출시했습니다.

2018

넷플릭스에서 공개된 ‘워터스쿨’ 다큐멘터리는 전 세계 6대 강의 주변에 살고 있는 여학생들의 경험을 통해 스와로브스키 워터스쿨의 노력을 기념하는 내용을 다루었습니다.

2021

스와로브스키 워터스쿨은 호주 현지 파트너인 Earthwatch Australia 및 Kids Teaching Kids와 함께 시드니에서 파일럿 프로젝트를 시작했습니다. 이 프로젝트는 현재 6개 대륙에서 활약을 펼치고 있는 워터스쿨의 기념비적인 이정표입니다.

스와로브스키 크리스털의 혁신

Title:2003

스와로브스키는 크리스털 요소에 대한 OEKO-Tex 100 인증을 획득하여 제품 및 생산 시설의 인체적, 생태학적 안전성을 확인했습니다.

2007

제품 부문별로 구성된 일련의 기준에 따라 모든 관련 제한 및 금지 물질을 표시하는 "CLEAR" 프로그램을 출시했습니다. 이 프로그램은 모든 제품 사양의 핵심 요소를 나타냅니다.

2009

스와로브스키는 특허받은 혁신적인 포뮬러를 통해 “가넷” 및 “인디안 시암”과 같은 카드뮴 무첨가* 레드 컬러 크리스털을 출시했습니다.

2012

어드밴스드 크리스털(Advanced Crystal) 프로그램을 출시하여 크리스털의 광도 및 광학적 품질을 유지하는 동시에 납 함량을 최대 90ppm까지 대폭 줄였습니다.

2017

어드밴스드 크리스털은 적용 가능한 가장 엄격한 환경 표준을 충족하는 선구적 포뮬러로 더욱 강화되었습니다. 납 함량을 최대 40ppm까지 더 낮춰서 무연* 크리스털 업계의 선두주자로 자리매김했습니다.

지속 가능한 건축

Title:2010

스위스 만네도르프에 새로 설립한 사무실 건물은 스위스의 미네르기(저에너지) 표준을 충족했습니다. 이 표준을 달성하기 위해 파사드와 빌딩 서비스 엔지니어링, 열활성 시스템의 구조를 통합했습니다. 또한 공기 밀폐, 일광량 사용, 난방, 단열, 흡열 유리, 열분배 및 환기 제어에 대한 요건을 충족했습니다.

2018

스와로브스키의 최첨단 지속 가능성 방식으로 설계된 쾌속 조형 시설, "Manufaktur"("Campus 311" 포함)가 문을 열었습니다. 노르웨이의 유명한 건축회사 스노헤타(Snøhetta)와의 협업으로 탄생한 이 7000제곱미터의 공간은 창의성과 상상력을 키우기 위해 설계되었습니다. Manufaktur 건물은 LEED(에너지 및 환경 디자인 리더십) 골드 인증을 획득하여 지속 가능한 혁신에 대한 스와로브스키의 약속을 보여주었습니다.

스와로브스키 재단

Title:2013

스와로브스키 재단은 5세대에 걸친 자선활동과 기부를 바탕으로 설립되었습니다.

2017

디자인 뮤지엄에 설립된 스와로브스키 재단 학습 센터는 디자인 교육을 위한 공간을 제공하고 매년 최대 4만 명의 학생들을 결집시키고 있습니다.

2021

스와로브스키 재단의 미래를 위한 창의적 인재(Creatives for Our Future) 프로그램은 UN 파트너십 사무국 고문과 함께 지속 가능성 분야에서 차세대 창의적 리더를 발굴하고 성장시키기 위해 고안된 글로벌 보조금 지원 제도입니다.

공급망의 책임 의식

Title:2014

스와로브스키의 책임감 있는 소싱 이니셔티브는 외부 공급망에 초점을 맞춘 프로그램으로, 2014년에 시작하여 오늘날까지 이어져오고 있습니다. 책임감 있는 소싱에는 공급업체들의 성과를 모니터링하고, 생산 공장에서 사회환경적 조건을 관리할 수 있도록 지원하는 것이 포함됩니다.

지속 가능한 혁신

Title:2018

Atelier Swarovski는 공정무역 인증 금과 Swarovski Created Diamonds, 실험실에서 생산된 에메랄드를 사용한 최초의 파인 주얼리를 위한 랜드마크 컬렉션을 출시했습니다.

2022

Swarovski 다시 빛나는 크리스털과 90%의 재생 베이스 메탈로 제작한 Fluenta 패밀리(FW22 출시)는 지속 가능성을 염두에 둔 첫 번째 컬렉션입니다. 이를 통해 귀중한 자원을 소모하기보다 용도를 변경해 이산화탄소 및 환경 발자국을 감축하는 역할을 합니다.

태양열의 힘

Title:2014

인도 푸네에 위치한 스와로브스키 공장은 옥상에 태양열 온수 시스템이 설치되어 있습니다.

2018

스와로브스키의 자회사 Marigot Thailand에 1400kWp의 태양광을 설치했습니다.

2022

스와로브스키는 바텐스에 있는 당사 시설 옥상에 300kWp의 태양광 발전 시스템을 설치했습니다.

스와로브스키 영향 평가

Title:2019

스와로브스키는 Trucost(S&P Global 소속)와 협력하여 스와로브스키 크리스털이 환경에 미치는 영향을 보여주는 선구적인 연구를 발표했습니다. 그 결과에 따르면, 스와로브스키 크리스털은 다른 주얼리 소재보다 환경 비용이 더 낮습니다.

2021

스와로브스키는 가장 많이 판매된 5개 제품에 대한 최초의 환경적 수명 주기 평가(LCA)를 실시했습니다. LCA 결과는 환경에 대한 부정적 영향을 줄이기 위해 스와로브스키가 해결해야 하는 주요 문제점을 정확하게 지적합니다.

새로운 시작

Title:스와로브스키는 당사의 크리스털 사업부 내에서 지속 가능성을 완전히 통합함으로써 최대 규모의 비즈니스 혁신을 시작했습니다. 이로써 스와로브스키는 향후 과제에 대비하고, 당사의 지속 가능성 비전과 전략, 프로그램에 대한 노력을 강화할 수 있었습니다.

글로벌 온난화 완화

Title:2021

Swarovski는 과학 기반 감축목표 이니셔티브(SBTi)에 동참하여 검증된 온실가스 감축 방식을 따르고, 2030년까지 직/간접 탄소배출량(Scope 1, 2)을 47%, 공급망 전체(Scope 3) 탄소배출량을 28% 감축하기 위해 노력하고 있습니다. 이는 수직적 통합을 통한 비즈니스 운영 방식의 실질적 변화를 나타냅니다.

2022

금년부터 Swarovski의 모든 아시아 제조 현장은 재생 가능한 에너지 인증을 통해 해당 지역의 태양광 발전소 및 풍력 발전소에서 100% 재생 가능한 전기를 공급받고 있습니다. 이 같은 노력의 결과로 스코프 2 배출을 현저하게 감소시킬 수 있었습니다.

스와로브스키의 영향 및 진행 상황 공개

Title:스와로브스키는 경제적, 환경적, 사회적 영향에 대한 투명성을 높이기 위한 노력의 일환으로, 지속 가능성 보고를 격년에서 연례 발표로 전환했습니다.