Our Long Legacy of Sustainability

Title:continuously investing to preserve the environment and to positively impact global and local communities.

Responsabilitate socială

Title:1900

Este înființat Clubul de muzică Swarovski și Clubul de ciclism Swarovski. Fondate inițial ca activități în cadrul companiei, cluburile au fost ulterior puse rapid la dispoziția tuturor persoanelor din oraș. Daniel Swarovski era un membru activ al ambelor cluburi.

1908-1909

Pe 25 iulie 1902, Daniel Swarovski devine membru al consiliului local din Wattens. În 1908, el este ales șef al consiliului local și la doar un an mai târziu, în 1909, începe construcția unei noi conducte care să aducă apă curată în oraș.

1909

După ce mai mulți lucrători ai companiei s-au mutat în oraș împreună cu familiile lor, vechea școală din Wattens devine neîncăpătoare pentru toți copiii. Marie Swarovski, soția lui Daniel, donează terenul clădirii pentru construirea unei noi școli.

1959

Swarovski oferă cursuri de instruire specializate care acoperă opt zone profesionale diferite, între care tăierea cristalelor: singurul de acest fel din Austria.

1960

Este înființat “The Daniel and Marie Swarovski Trust”, care oferă burse studenților care locuiesc în Tirol, au un istoric de note bune și provin din familii cu venituri mici.

1978

Este format un "Colegiu vocațional" la sediu, pentru a oferi ucenicilor o bază solidă pentru implementarea abilităților și aptitudinilor la locul de muncă. Swarovski este una dintre puținele companii din Austria care are un astfel de colegiu.

Utilizarea puterii apelor

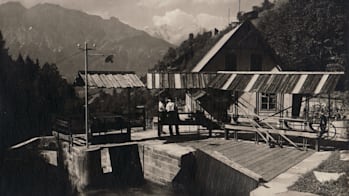

Title:1907

Ausserachen, prima hidrocentrală mare a companiei, este construită. Cele trei turbine Pelton au oferit o “Putere Swarovski” curată mașinilor de tăiere, lumină în zonele de lucru, precum și în zone întinse din Wattens și din comunitățile montane învecinate.

1951

Hidrocentrala Ausserachen este îmbunătățită pentru a furniza o putere de 750 KW.

1961

Cererea tot mai mare pentru energie curată duce la construirea centralei Innerachen, cu putere de 2.200 KW prin două turbine Francis.

1983

Hidrocentrala Wattenbach este construită, în colaborare cu fabrica de hârtie din Wattens. Această centrală produce în medie 57 GWh pe an.

1984

Cu o turbină Pelton suplimentară cu două duze, capacitatea standard a centralei electrice Innerachen crește la aproximativ 1,35 GWh pe an.

1995

Considerată un proiect model pentru producerea de energie ecologică în Alpi, centrala electrică “Haneburger” intră în funcțiune. De atunci a livrat aproximativ 18,5 GWh pe an.

2001

Toate centralele Swarovski sunt recunoscute oficial de autoritățile austriece ca producători de "energie ecologică" certificată.

O casă pentru fiecare

Title:1947

Piatra de temelie a unei noi construcții de locuințe pentru angajații companiei a fost ridicată la “Kreuzbichl” (un deal în apropiere de Wattens). Construcția a fost finalizată în 1950. Până în prezent, au fost realizate mai multe proiecte de locuințe.

1948

Un birou de asistență socială deținut de companie este înființat pentru a se ocupa de problemele sociale și financiare ale angajaților. Politica noastră privind locuințele a oferit credite cu rate scăzute ale dobânzilor, ajutor substanțial pentru construcția locuințelor și sprijin pentru urgențe financiare.

1951

Începe/este finalizată construcția a două complexe rezidențiale pentru angajații Swarovski Optik din Absam și pentru angajații Swarovski din Volders, Austria.

1952

Începe/este finalizată construcția unui complex rezidențial suplimentar pentru angajații Swarovski din Fritzens, Austria

2005

O ceremonie de inaugurare are loc pentru cele 58 de șiruri de case noi pentru angajați. Acest proiect ajută angajații să închirieze sau să cumpere spațiu pentru locuit la prețuri moderate.

O resursă valoroasă

Title:1970

Primul turn de răcire cu circulație pentru răcirea compresoarelor cu aer comprimat a fost pus în funcțiune. Acest lucru a economisit aproximativ 90% din apa necesară pentru răcire.

1978-1982

Stația de epurare a apelor uzate începe să funcționeze, purificând toată apa care iese din fabrica Stației 1. O serie de inițiative ulterioare a extins purificarea apei la Stația 2, extinzând și capacitatea instalației de purificare și împărțind apa tratată în apă folosită la lustruire și apa folosită la tăiere.

Aer mai curat

Title:1984

Swarovski importă în Germania petrol cu niveluri reduse de sulf pentru încălzire, mărind cheltuielile anuale indirecte cu echivalentul a 210.000 EUR în prezent, dar reducând emisiile de dioxid de sulf cu 60 de tone. Astfel, companiei i se acordă premiul “Green Branch” pentru mediu de către guvernul statal federal din Tirol.

1990

Swarovski adoptă gazul natural. De acum înainte, gazul înlocuiește păcura pentru generarea căldurii și topirea cristalelor, reducând astfel emisiile respective de CO2 cu 30%.

1996

Departamentul de creare a sticlei este dotat cu filtre de praf specializate noi și un sistem de extracție nou. Acestea au permis reducerea emisiilor, prevenirea poluării și evitarea riscurilor la adresa sănătății lucrătorilor cu mult sub limitele legale.

Swarovski Waterschool

Title:2000

Se deschide prima Swarovski Waterschool la Parcul Național Hohe Tauern din Austria, în cadrul bazinului Dunării. Este inițiat un program educațional, care învață atât copiii, cât și tinerii adulți despre importanța și deficitul de apă.

2006

Se deschide Swarovski Waterschool India, primul proiect în afara Austriei, în jurul Parcului Național Keoladeo în Rajasthan din bazinul fluviului Gange.

2008

Swarovski Waterschool începe să funcționeze în șase regiuni de-a lungul fluviului Yangtze din China și în 20 de comunități din districtul Kanungu în Uganda.

2014

Waterschool ajunge în statul Para din nordul Braziliei, axându-se pe educație privind apa și mediul prin intermediul școlilor și al educației participative bazate pe comunitate.

2016

Trei proiecte pilot sunt lansate împreună cu diferite organizații pentru a evidenția sursele de apă locale. NGRREC: Fluviul Mississippi; Raks Thai Foundation; bazinul râului Chao Praya; Fundação Amazonas Sustentável: Amazon.

2017

Lucrând în colaborare cu ONG-urile partenere, Swarovski Waterschool lansează ediția globală a materialelor sale pentru învățare și predare, ‘Drops of Knowledge for Rivers of Change’, pe site-ul web Swarovski Waterschool.

2018

Lansarea documentarului ‘Waterschool’ pe Netflix, care urmărește experiențele unor tinere studente care trăiesc de-a lungul a șase dintre cele mai mari fluvii ale lumii și celebrează eforturile Swarovski Waterschool.

2021

Împreună cu partenerii locali Earthwatch Australia și Kids Teaching Kids, Swarovski Waterschool lansează proiectul său pilot în Sydney, Australia. Acesta marchează un reper emoționant pentru proiectul Waterschool, care este acum activ pe șase continente.

Inovațiile Swarovski Crystal

Title:2003

Swarovski obține certificarea OEKO-Tex 100 pentru componentele cristalelor, confirmând siguranța pentru oameni și mediu a produselor și a centrelor de producție.

2007

Lansarea programului "CLEAR", format dintr-un set de criterii structurate în funcție de segmentul de produs, afișând toate substanțele restricționate și interzise relevante. Acesta constituie o parte importantă a tuturor specificațiilor de produs.

2009

Swarovski lansează cristale de culoare roșie fără cadmiu*, cum ar fi “Garnet” și “Indian Siam”, prin intermediul formulelor inovatoare brevetate.

2012

Lansarea programului Advanced Crystal, care reduce drastic conținutul de plumb la maximum 90 ppm (părți per milion), fără să compromită strălucirea și calitatea vizuală a cristalelor noastre.

2017

Advanced Crystal este îmbunătățit cu formule inovatoare care îndeplinesc cele mai exigente standarde aplicabile în domeniul protecției mediului. Nivelurile de plumb sunt reduse în continuare până la maximum 40 părți per milion, devenind un lider al industriei în ceea ce privește cristalele fără plumb*.

Arhitectură sustenabilă

Title:2010

Clădirea de birouri (Mannedorf) dezvoltată recent în Elveția îndeplinește standardul Swiss Minergie (consum redus de energie). Acest lucru se realizează prin structurarea integrată a façțadei, ingineria serviciilor de construcție și sisteme termoactive. În special, au fost îndeplinite cerințele privind etanșeitatea la aer, utilizarea pe lumină naturală, încălzirea, izolarea termică, sticlă care absoarbe căldura, distribuția căldurii și ventilația controlată.

2018

Inaugurarea și deschiderea "Manufaktur" (împreună cu "Campus 311"), centrul nostru de prototipare rapidă, de ultimă generație, proiectat sustenabil. Designul acestui spațiu de 7.000 de m2 - o colaborare cu arhitecții norvegieni de la Snøhetta - este conceput pentru a stimula creativitatea și imaginația. Clădirea Manufaktur demonstrează angajamentul nostru pentru inovație sustenabilă prin obținerea certificării Gold LEED (Leadership in Energy and Environmental Design).

Fundația Swarovski

Title:2013

Este înființată Fundația Swarovski, bazată pe cinci generații de activități filantropice și de caritate.

2017

Centrul de invățare al Fundației Swarovski este inaugurat la Muzeul Designului, oferind un spațiu pentru educația în materie de design și strângând laolaltă până la 40.000 de elevi anual.

2021

Fundația Swarovski: Creatives for Our future este un nou program de burse la nivel global, conceput cu un consilier, Oficiul Națiunilor Unite pentru Parteneriate, pentru a identifica și accelera generația viitoare de lideri creativi în domeniul sustenabilității.

Responsabilitatea lanțului de aprovizionare

Title:2014

Lansarea Inițiativei de aprovizionare responsabilă, un program care se axează pe lanțul nostru de aprovizionare extern care continuă în prezent. Aprovizionarea responsabilă implică monitorizarea performanțelor furnizorilor și sprijinirea acestora în gestionarea condițiilor socio-ecologice la fabricile lor de producție.

Inovație sustenabilă

Title:2018

Atelier Swarovski lansează o colecție emblematică: primele sale bijuterii rafinate care utilizează aur provenit din comerț echitabil, Swarovski Created Diamonds și smaralde dezvoltate în laborator.

2022

Realizată cu cristale Swarovski reinventate și 90% metal de bază reciclat, familia Fluenta (lansată în FW22) este prima noastră colecție orientată spre sustenabilitate. Reutilizează resursele prețioase în loc să consume noi materii prime, ceea ce duce la o reducere a emisiilor de CO2 și a amprentei ecologice.

Puterea soarelui

Title:2014

Un sistem de încălzire a apei cu energie solară pe acoperiș este montat la fabrica noastră din Pune, India.

2018

Instalație fotovoltaică de 1400 kWp în Marigot, Thailanda

2022

Swarovski finalizează instalarea unui sistem fotovoltaic de 300 kWp pe acoperișul centrelor noastre din Wattens.

Evaluarea impactului nostru

Title:2019

Swarovski publică un studiu inovator în parteneriat cu Trucost (parte a S&P Global), arătând impactul pe care cristalele Swarovski îl au asupra mediului. Rezultatele dezvăluie faptul că cristalele Swarovski au un cost mai redus asupra mediului decât alte materiale pentru bijuterii.

2021

Swarovski desfășoară prima Evaluare completă a ciclului de viață al produselor în raport cu mediul, pentru 5 dintre cele mai vândute articole ale noastre. Rezultatele Evaluării LCA identifică zonele pe care trebuie să le abordăm pentru a reduce impactul negativ asupra mediului.

Un nou început

Title:Swarovski inițiază cea mai mare transformare de până acum pentru activitatea noastră, integrând complet sustenabilitatea în cadrul Swarovski Crystal Business. Acest lucru ne-a permis să ne pregătim pentru provocările viitoare și să ne consolidăm angajamentul privind viziunea, strategia și programele noastre dedicate sustenabilității.

Diminuarea efectelor încălzirii globale

Title:2021

Swarovski aderă la inițiativa Science Based Targets (SBTi), o abordare verificată de limitare a gazelor cu efect de seră și se angajează să reducă emisiile absolute de GES din categoriile 1 și 2 cu 47% și emisiile din categoria 3 cu 28%, până în 2030. Acest lucru reprezintă o schimbare importantă a modului în care operează afacerea noastră integrată pe verticală.

2022

Începând din acest an, toate unitățile noastre de producție din Asia se aprovizionează cu energie electrică 100% regenerabilă de la centrale fotovoltaice și ferme eoliene din regiune, prin intermediul certificatelor de energie regenerabilă. Acest efort ne permite să reducem în mod tangibil emisiile noastre de tip Scope 2.

Dezvăluirea impactului și progresului nostru

Title:Ca parte a angajamentului nostru pentru o mai mare transparență asupra impactului nostru economic, ecologic și social, înlocuim raportarea bienală asupra sustenabilității cu una anuală.